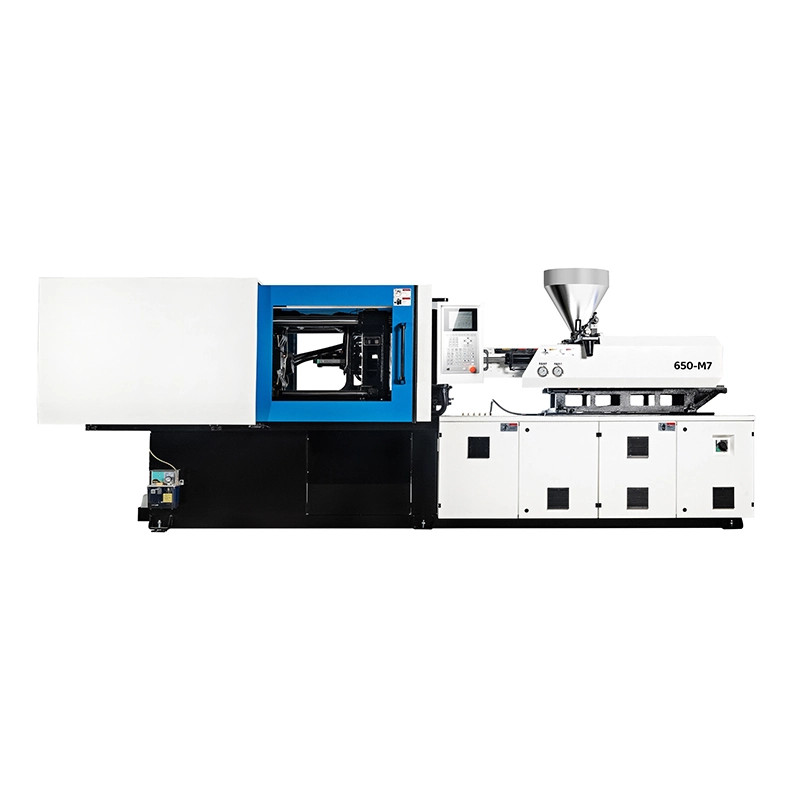

High-Performance Injection Molding Machine for PET Preforms

Key Features and Benefits:

● Exceptional Precision & Repeatability

● Optimized Injection System

● High-Speed Production Cycles

● Integrated Drying & Handling

● User-Friendly Control & Monitoring

Main Technical Parameter

|

mm |

650 |

710 |

780 |

880 |

920 |

|||||||

|

mm |

710x670 |

760X710 |

830X810 |

860*840 |

930*930 |

|||||||

|

mm |

495x470 |

530x500 |

580x565 |

600*588 |

675*665 |

|||||||

|

mm |

250~710 |

260~750 |

280~830 |

320-870 |

370-920 |

|||||||

|

ton |

19.8 |

21.5 |

25.0 |

25.0 |

25 |

|||||||

|

mm |

180 |

210 |

220 |

220 |

220 |

|||||||

|

unit |

13 |

13 |

17 |

17 |

21 |

|||||||

|

MPa |

17.5 |

17.5 |

17.5 |

17.5 |

17.5 |

|||||||

|

|

1900 |

2700 |

3350 |

2700 |

3350 |

5400 |

3350 |

5000 |

5400 |

6800 |

9000 |

11000 |

|

mm |

76 |

84 |

95 |

84 |

95 |

105 |

95 |

100 |

105 |

108 |

116 |

125 |

|

cm³ |

1338 |

1829 |

2623 |

1829 |

2623 |

3897 |

2623 |

3299 |

3897 |

4397 |

5707 |

7363 |

|

g |

1552 |

2121 |

3042 |

2121 |

3042 |

4520 |

3042 |

3826 |

4520 |

5496 |

7133 |

8541 |

|

L/D |

24 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

MPa |

141 |

147 |

127 |

147 |

127 |

139 |

127 |

154 |

139 |

154 |

156 |

134 |

|

g/s |

492 |

588 |

788 |

588 |

788 |

925 |

788 |

862 |

925 |

1088 |

1197 |

1390 |

|

mm |

94 |

92 |

96 |

92 |

96 |

92 |

96 |

92 |

92 |

90 |

88 |

80 |

|

mm |

295 |

330 |

370 |

330 |

370 |

480 |

370 |

480 |

480 |

480 |

540 |

600 |

|

rpm |

158 |

141 |

131 |

141 |

131 |

124 |

131 |

124 |

124 |

110 |

100 |

90 |

|

ton |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

14.2 |

|

mm |

460 |

460 |

500 |

460 |

500 |

460 |

500 |

460 |

460 |

500 |

460 |

460 |

|

kW |

42 |

50 |

62 |

50 |

62 |

32+42 |

62 |

42+50 |

32+42 |

50+50 |

50+62 |

62+62 |

|

unit |

4+1 |

4+1 |

5+1 |

4+1 |

5+1 |

5+1 |

5+1 |

5+1 |

5+1 |

5+1 |

5+1 |

5+1 |

|

kW |

40 |

45 |

52 |

45 |

52 |

60 |

50 |

58 |

60 |

64 |

64 |

78 |

|

KW |

42 |

42 |

80 |

42 |

80 |

100 |

80 |

100 |

100 |

100 |

100 |

100 |

|

L |

500 |

590 |

790 |

590 |

790 |

950 |

790 |

1000 |

950 |

1150 |

1300 |

1300 |

|

ton |

13.4 |

13.5 |

13.6 |

15.8 |

15.9 |

16.1 |

24 |

24.1 |

24.3 |

27 |

30 |

33 |

|

M |

6.8*1.6 |

7.0*1.6 |

7.2*1.6 |

7.45*1.71 |

7.7*1.71 |

8*1.71 |

8.23*1.7 |

8.3*1.7 |

8.5*1.7 |

9.5*2.4 |

10.2*2. |

11.2*2.72 |

|

5*2.2 |

5*2.2 |

5*2.2 |

*2.25 |

*2.25 |

2.25 |

8*2.3 |

8*2.3 |

8*2.3 |

*2.8 |

5*2.8 |

*2.88 |

|

Key Features & Technological Advantages

Exceptional Precision & Repeatability: Equipped with a high-response servo system and a closed-loop control, our machine ensures shot-to-shot consistency in preform weight, wall thickness, and intrinsic viscosity (IV). This guarantees that every preform you produce meets the most stringent quality standards.

Machine Display

Preforms and Bottles

Primary Applications

This machine is the ideal solution for manufacturing PET preforms used across a wide range of industries, including:

● Beverage Packaging: Producing preforms for water, carbonated soft drinks (CSD), juices, and ready-to-drink teas.

● Food & Edible Oil: Creating safe and hygienic containers for cooking oil, sauces, and other liquid food products.

● Pharmaceutical & Cosmetic: Manufacturing preforms for bottles that hold medicines, syrups, and personal care products, where clarity and chemical resistance are paramount.

● Household & Industrial Chemicals: Producing durable containers for detergents, cleaning agents, and other chemical solutions.

FAQ

Customer Review

Discover what our clients have to say