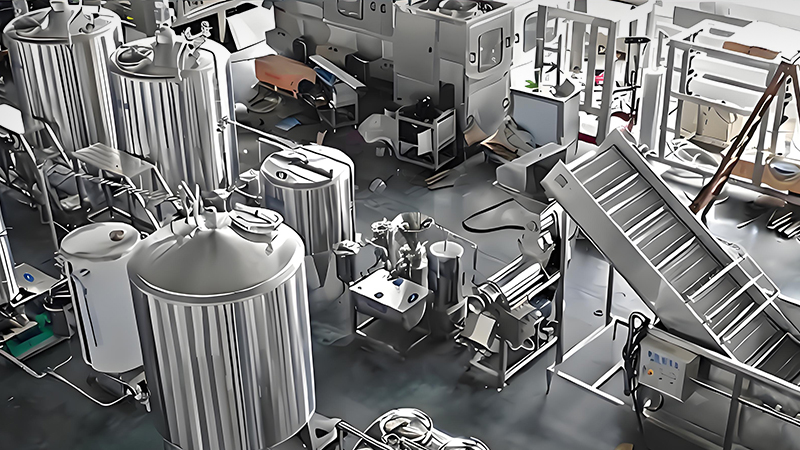

Carbonated Drinks Production Line

Carbonated Drinks Production Line

This machine is the heart of the production line for carbonated drinks. It ingeniously integrates three critical steps into one compact system . It first blow-molds PET preforms into finished bottles , then immediately fills them with the carbonated beverage, and finally applies and tightens the caps . This "one-step" process is particularly vital for carbonated drinks because it allows the bottles to be filled and sealed immediately after being formed, which helps to preserve the carbonation (fizz) and minimize the loss of gas . This 3 in 1 machine includes an anti-drip filling valve system to maintain a clean production line and ensure accurate fill levels.

Automatic Labeling Machine

Once the bottles are filled and capped, they move to the labeling station. Here, a high-speed automatic labeler accurately applies labels to the bottles . Modern labeling Machine are versatile and can handle various label types for different marketing needs. They ensure every bottle has a professional and brand-consistent appearance with high application accuracy.

Film Wrapping Machine

The final stage in the line is bundling individual bottles for distribution. A film wrapping machine, or multi-packer, groups bottles into stable packs (like 6-packs or 12-packs) and securely wraps them in transparent or printed shrink film . This makes the products more convenient for consumers to carry and prepares them for efficient palletizing and retail display.

This versatile production line is specifically designed for packaging a wide array of carbonated beverages in PET bottles. Its primary applications include:

▪Carbonated Soft Drinks: Such as colas, lemonades, and other flavored sparkling beverages .

▪Sparkling and Seltzer Water: Perfect for producing plain or flavored sparkling water.

▪Tonic Water and Other Mixers.

By combining high-speed automation with a hygienic and integrated design, a carbonated drinks production line is a fundamental investment for any company aiming to build an efficient, profitable, and scalable operation that delivers a consistently high-quality, fizzy drink to the market.