Faygo Union Linear Blowing-Filling-Capping Machine: Integrated Efficiency for Bottling Lines

Key Features and Benefits:

● Compact Linear Design and High Efficiency

● Advanced Control and Operation

● Energy and Resource Efficient

● Enhanced Hygiene and Contamination Prevention

Main Technical Parameter

|

Technical deatils for Series CGX Linear type Blowing-filling-capping Machine: |

||||

|

Model No. |

CGX6-16-8 |

CGXX6-18-8 |

CGXX8-24-10 |

|

|

Cavity qty. |

6 |

6 |

8 |

|

|

Filling valve qty. |

16 |

18 |

24 |

|

|

Capping head qty. |

|

8 |

10 |

|

|

8 |

||||

|

Bottle |

Max.Bottle volume(ml) |

2000 |

2000 |

750 |

|

specifications |

Max.Bottle height(mm) |

328 |

328 |

300 |

|

|

Max.Bottle body diameter(mm) |

105 |

105 |

75 |

|

Preform |

Bottle neck inner diameter(mm) |

20-25 |

20-25 |

20-25 |

|

Max.Preform length(mm) |

150 |

150 |

140 |

|

|

Output(500ml,17g bottle for example) |

10,000-11,000 |

12,000-13,000 |

15,000-16,000 |

|

Product Introduction

The Faygo Union Linear Blowing-Filling-Capping Machine represents a significant advancement in integrated bottling technology. This combiblock system seamlessly combines blowing, filling, and capping processes into a single, streamlined unit, designed to enhance production efficiency, ensure product hygiene, and reduce operational costs. Ideal for small to medium-scale production plants, this machine is engineered to handle a variety of liquid products, including mineral water, beverages, juices, and oils

Key Features and Technological Advantages

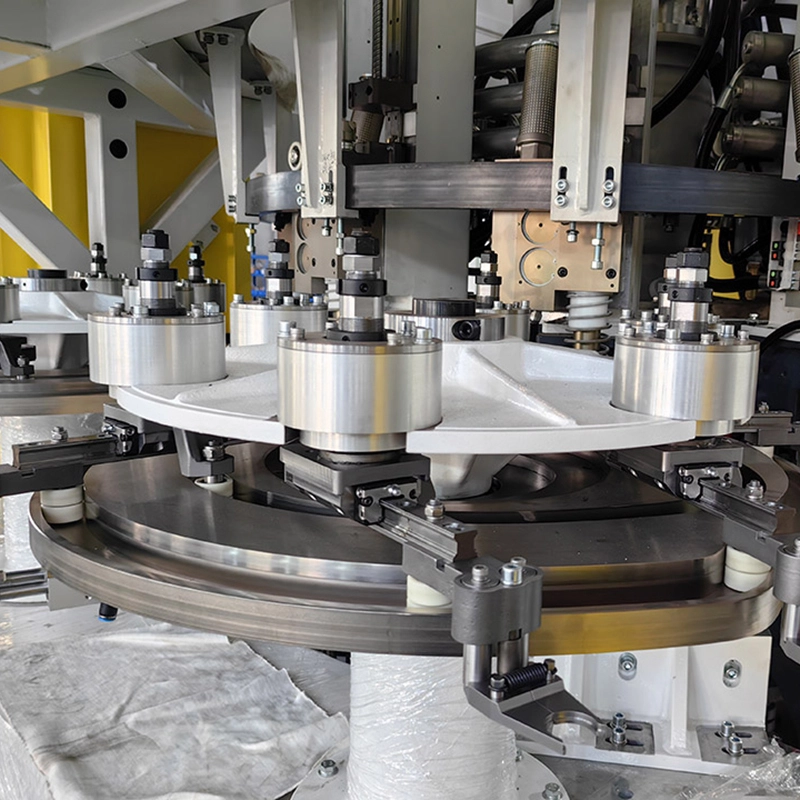

Machine Display

Primary Applications

The versatility of the Faygo Union Linear Machine makes it suitable for a wide range of applications in the liquid packaging industry. It is an ideal solution for:

● Bottled Water Plants: Efficiently produces bottles for mineral and pure drinking water.

● Beverage Industry: Capable of handling non-carbonated liquids such as juices and teas.

● Edible Oil and Other Liquids: The technology is also adaptable for filling edible oils and other non-carbonated liquid products.

FAQ

Customer Review

Discover what our clients have to say