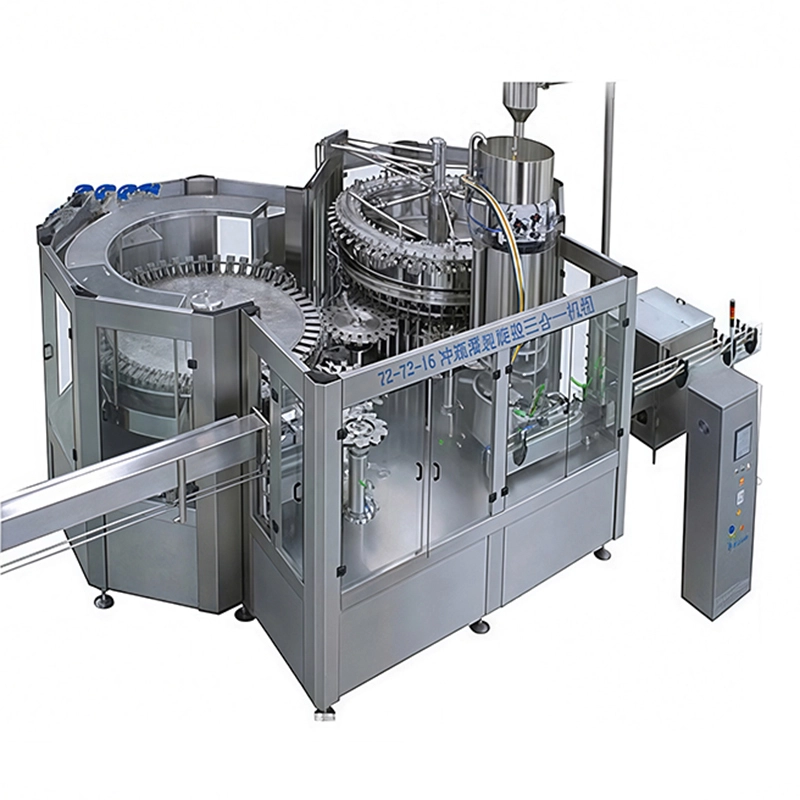

Edible Oil Filling Machine

The edible oil filling machine is a fully automatic equipment designed to fill various types of edible oils with high accuracy and efficiency. It is widely used in food processing factories, oil production plants, and packaging companies that need stable and hygienic filling solutions. This machine is suitable for a wide range of oil products, including sunflower oil, soybean oil, palm oil, peanut oil, olive oil, and blended cooking oils. It can work with different bottle shapes and sizes, making it ideal for small bottles, medium containers, and large-volume jerry cans.

This filling machine is built to deliver stable production output. Depending on the model, it can reach a production capacity ranging from 1,000 to 6,000 bottles per hour. The advanced flowmeter or piston filling system ensures every bottle is filled with consistent volume, even when working with high-viscosity oils. Its precision control helps reduce product waste and improves overall production efficiency. The machine is equipped with a user-friendly PLC control system and touchscreen interface, allowing operators to adjust parameters easily and monitor filling performance in real time.

Flexible customization

The edible oil filling machine also offers flexible customization. Customers can choose different filling heads—from 4, 6, 8, 12, up to 24 heads—based on their required speed and production scale. Optional equipment such as automatic capping machines, labeling machines, conveyors, and bottle unscramblers can be integrated to form a complete oil bottling line. This helps customers achieve a fully automated workflow from bottle feeding to final packaging.

In daily operation, the machine is known for its high accuracy, low energy consumption, and easy operation. It supports quick changeovers for various bottle types, allowing manufacturers to switch between different oil products efficiently. Whether the customer is producing edible oil for retail packaging, restaurant supply, or industrial distribution, this machine provides a stable and cost-effective filling solution.

Maintain high product quality across

With its precise filling performance, strong reliability, and flexible configuration, the edible oil filling machine becomes a valuable choice for manufacturers aiming to improve production capacity and product consistency. It helps customers reduce labor costs, increase output, and maintain high product quality across every batch.

Machine Display

FAQ

Customer Review

Discover what our clients have to say